Services

Cabomet has been present in high vacuum metallization and coating finisching for many years, and also in the plastic injection extrution fields.

We are able to increase the value of each project thanks to the solidity of a large network of trusted collaborators and support the customer at every steps of the project, from the design and construction of the molds, to the extrusion, from metallization to the finishing of the items. In addition, we are leader in the production of plastic components for cups, trophies and award items.

Applications

Our processes

Technology

Metallization and Painting

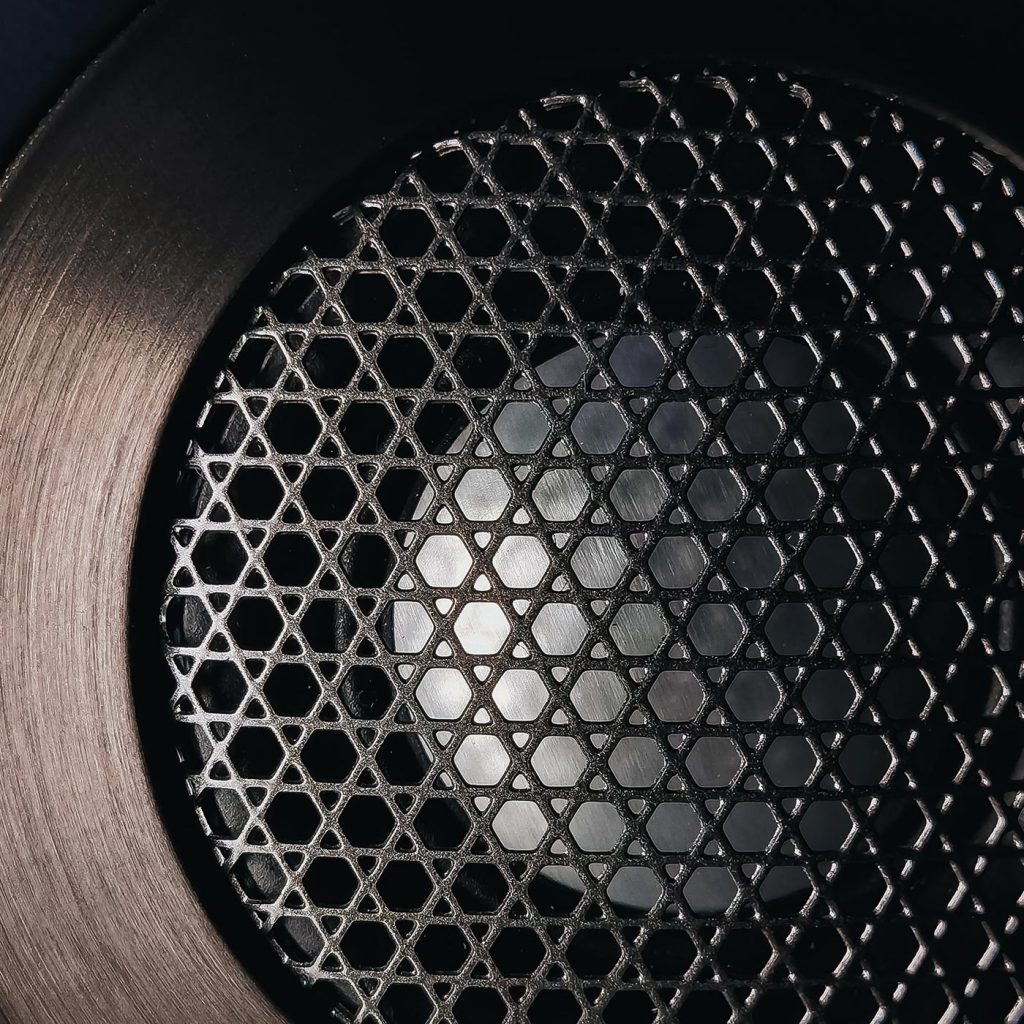

Metallization represents a sustainable, fast and clean process. It consists in the physical vapour high vacuum deposition of different metal with a pureness until to 99,9%.

Metallizing

Process

The metallization is based on the sublimation of aluminum under high vacuum. First of all the artifact is pretreated in order to create the correct surface, then through a physical process the aluminum becomes vapour and deposites on the desired material.

Technology

Plastic injection extrusion

In order to offer a complete service to our customers, we also have the plastic injection extrusion technology, starting from executive design and mold production.

Custom made

Make your product

Discover more

newsletter subscription

Subscribe to our newsletter and stay updated on all our latest news.

Headquarter

CABOMET S.R.L.

Via Piersanti Mattarella, 57

30037 – Gardigiano di

Scorzè (VE) – ITALY

Contacts

Tel. +39 041 5830300

Fax +39 041 5830301

Email: info@cabomet.it

© 2021 CABOMET S.R.L. – All Rights Reserved.

P.IVA 04678770274 – REA VE440074

Credit: Hangar Design Group